理解了扭矩曲线,很多螺栓拧紧问题都可以迎刃而解!

Torque-angle curve analysis is known to be one of the most basic and practical methods of determining not only what the fastener went through during the tightening process, but also the integrity of the joint itself. The ability to interpret the resulting signature of the tightening path gives an understanding of the installation, and in some cases the failure characteristics of a bolted joint.

首先看看螺栓拧紧变形的应力曲线;

然后,让我们来初步认识扭矩曲线:

扭矩(torque)和拧紧旋入角度(angle)

扭矩+角度的控制扭矩曲线

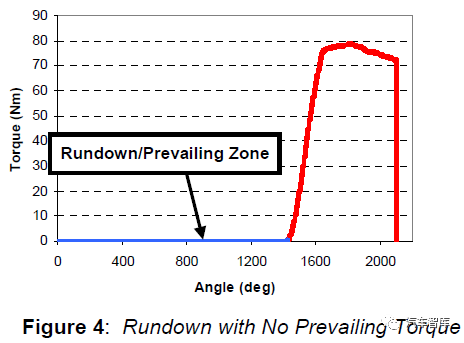

螺栓套入拧紧过程无拧入扭矩

拧入过程中有锁紧设计(如密封圈)产生的扭矩

拧入中自攻产生的扭矩

预置扭矩(前端通过的峰值扭矩为松脱扭矩;在扭矩设置时会参考到)

在进入弹性变形阶段前的过渡区域

硬连接和软连接的扭矩曲线对比

不同摩擦系数,产生的扭矩曲线对比:摩擦系数越大,扭矩越大!

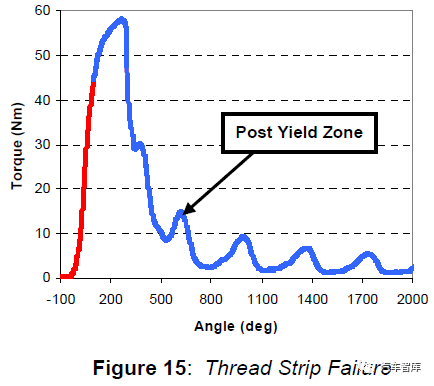

螺栓断裂失效,就是进入了屈服区域。

螺栓扭矩设定的实际应用,如上图扭矩窗口区域;一般选接近进入弹性区域的扭矩值(参考摩擦系数,拧紧工具能力(比如过冲量)等。

这只是一个粗浅的螺栓拧紧曲线图示。